The Intricate World of Diecasting: Precision in Manufacturing

The Intricate World of Diecasting: Precision in Manufacturing

Blog Article

Diecasting is an extremely specialized manufacturing technique that converts melting metal into precise components using high-pressure molds. The technique is now indispensable for a wide range of industries such as electronics, aerospace, automotive and even consumer products due to its capacity to fabricate complex designs with extraordinary reliability and accuracy. In combining the principles of metalworking with the latest in engineering diecasting can provide unrivalled precision and efficiency, making it the foundation of the modern production. This article explores the intricate realm of diecasting looking at its procedure, advantages, and wide-ranging applications.

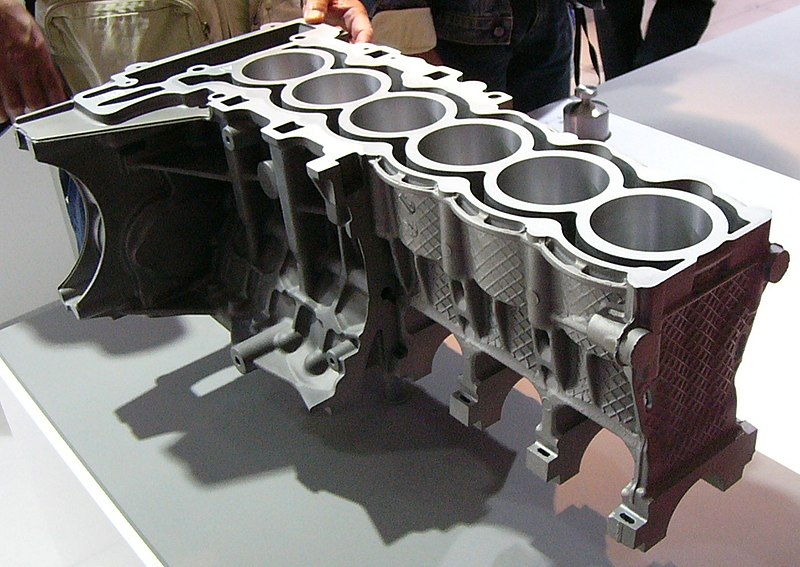

At the core of diecasting is the usage of molds or dies. Dies are created with high-quality steel in order to stand up to the tough conditions encountered in making. The dies are designed precisely, usually incorporating intricate details and fine tolerances in order to guarantee the accuracy of the final product. The process of diecasting involves melts of metal - commonly zinc, aluminum, magnesium, or copper-is injected into the dies at high pressures. This rapid injection and the process of solidification results in parts with outstanding dimensional stability as well as a flawless surface finish. This reduces the requirement for additional processing or finishing. The preciseness of the dies allows for the production of intricate geometries which are difficult or impossible to accomplish using other manufacturing techniques.

One of the biggest advantages of diecasting is the ability to produce mass quantities. When the dies are made it is possible to produce thousands of identical parts that are identical with little variation. The high degree of repeatability is essential for industries which require huge quantities of identical parts. Diecasting is also known as a material that is efficient. This process produces very little debris, as any metal that is not used is reused in subsequent casting cycles. This reduces not just costs for materials, but it also encourages environmentally sustainable practices in manufacturing, by minimizing resource consumption and waste. High efficiency, high speed of the material, and high efficiency make diecasting an attractive option for companies looking to improve the efficiency of their processes.

Diecasting also offers significant benefits in terms of mechanical properties. Diecast components typically exhibit excellent strength and durability because of the fine-grain structure created during the fast melting of the metal. These components are perfect for use in applications that require the highest performance and durability. Moreover, the process allows the use of slim walls and complex elements without compromising their structural quality. This feature is especially useful in the automotive and aerospace industries where weight reduction while maintaining strength is critical. Being able to create robust, lightweight components enhances fuel efficiency as well as performance of aircrafts as well as vehicles. To get further information please head to Senadiecasting

Diecasting materials are crucial in determining the properties and the performance of the final product. Aluminum is one of the most commonly used materials due to its high strength-to-weight ratio, resistance to corrosion, and good thermal and electrical conductivity. Zinc alloys are also very popular with their high strength, ductility, as well as the capability to create parts with intricate details. Magnesium alloys offer the benefit that they are the tiniest structural metal. This makes them ideal for applications in which weight reduction is essential. Copper alloys are somewhat less popular, are used because of their excellent electro-conductive properties and corrosion resistance. The selection of the material is based upon the specifications of the project, which includes physical properties, climate conditions, as well as cost considerations.

Diecasting is a very productive and flexible manufacturing method that is integral to producing complex metal parts with high precision and consistency. Its ability to create components with fine details, tight tolerances, and polished surfaces makes it an indispensable tool for all sectors, from automotive to aerospace, to consumer electronics, and even beyond. The use of different material types further increases the flexibility of diecasting. It allows companies to choose the most suitable alloy for their specific needs. With the advancement of technology and as the demand for premium, efficient components grows the use of diecasting will be an essential element on the manufacturing scene, driving innovation and excellence when it comes to production.